Recognizing the Uses of a Galvanometer Scanner in Accuracy Dimension Applications

Galvanometer scanners have actually emerged as essential devices in precision measurement applications, specifically due to their amazing ability to control laser beam of lights with extraordinary rate and precision. Understanding the functional auto mechanics and varied applications of these scanners exposes not only their importance yet also the advantages they confer in keeping sector requirements.

Just How Galvanometer Scanners Job

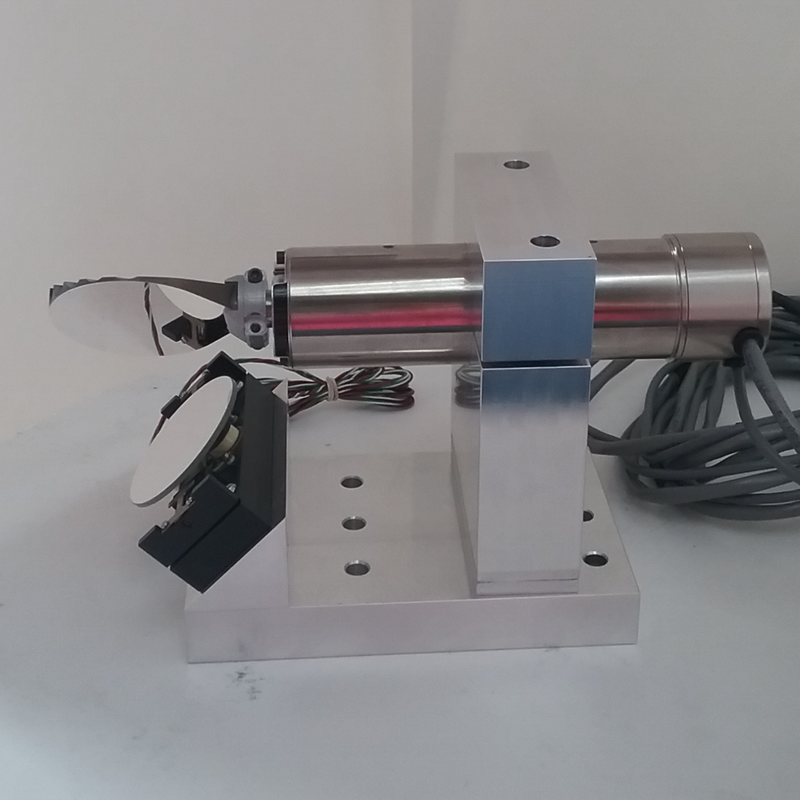

A galvanometer scanner runs by making use of the concept of electromagnetic deflection to regulate the setting of a beam. This gadget contains a coil suspended in a magnetic field, where electric currents travelling through the coil develop a torque that causes it to rotate. The angle of deflection is symmetrical to the current, enabling specific control over the light beam's placement.

Generally, galvanometer scanners use a combination of mirrors and lenses to guide the beam across a desired surface or medium - galvanometer scanner. The rapid feedback time of the galvanometer enables high-speed scanning and exact positioning, making it suitable for different applications. The responses mechanism, commonly integrated into the system, ensures that the beam stays straightened with the designated target by adjusting the present based on the real deflection angle

The construction materials and style of the galvanometer, including the coil resistance and the stamina of the magnetic field, are essential aspects that influence its performance. These aspects add to the scanner's level of sensitivity, resolution, and general operational performance. Comprehending how galvanometer scanners job is vital for optimizing their use in accuracy measurement applications.

Applications in Laser Scanning

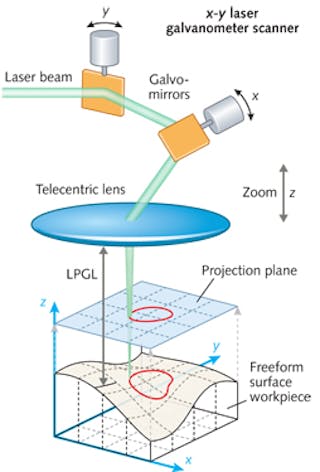

Galvanometer scanners play a vital role in laser scanning applications, where precision and speed are critical. These gadgets use a turning mirror system to guide laser beams with high accuracy across numerous surfaces, making them vital in fields such as material handling, 3D scanning, and laser noting. The capacity of galvanometer scanners to accomplish quick angular motion enables reliable raster scanning, which is crucial for producing high-resolution and in-depth photos.

In industrial setups, galvanometer scanners are important in laser cutting and engraving, where they supply consistent and repeatable control over the laser light beam's position. This capacity ensures that intricate styles can be implemented with minimal errors, boosting manufacturing quality. In the world of 3D laser scanning, these scanners promote the capture of intricate geometries by rapidly brushing up the laser beam of light over an object, generating exact factor clouds for digital modeling.

Furthermore, the integration of galvanometer scanners in laser display modern technologies showcases their convenience. They make it possible for the production of vibrant aesthetic results in enjoyment and advertising, further highlighting the importance of precision in laser scanning applications across varied markets.

Function in Biomedical Imaging

Making use of galvanometer scanners in biomedical imaging considerably improves the accuracy and rate of data purchase in various medical applications. These scanners facilitate accurate and quick positioning of laser light beams, which is crucial for high-resolution imaging strategies such as optical comprehensibility tomography (OCT) and confocal microscopy. By using galvanometer scanners, healthcare professionals can obtain thorough cross-sectional photos of tissues, permitting early diagnosis and effective monitoring of conditions.

In addition to enhancing image top quality, galvanometer scanners contribute to the efficiency of imaging treatments. Their capacity to swiftly and accurately direct laser beams lessens motion artifacts, boosting the integrity of the information collected. This is particularly important in vibrant settings where patient motion could compromise picture stability.

In addition, the flexibility of galvanometer scanners to numerous wavelengths and imaging modalities makes them integral to sophisticated biomedical research study. They can be used in fluorescence imaging, allowing scientists to study mobile processes and molecular interactions with unprecedented clarity. As the area of biomedical imaging proceeds to develop, the function of galvanometer scanners will certainly continue to be pivotal in driving innovations that improve analysis abilities and boost patient results.

Relevance in Industrial Processes

Additionally, galvanometer scanners are crucial in optical assessment systems, where they allow real-time tracking of production lines. By quickly scanning products for problems, these systems assist maintain rigorous quality assurance requirements, making sure that only items fulfilling specifications continue to the following stage of production. Additionally, in the world of 3D printing, galvanometer scanners add to the precision of layer deposition, dramatically affecting the last item's accuracy and architectural stability.

In sectors such as electronics and vehicle, the capability to carry out accurate dimensions and modifications in real-time translates to raised efficiency and performance. The usage of galvanometer scanners not just improves functional capabilities however additionally plays a crucial function in driving advancement across numerous industrial sectors.

Benefits of Accuracy Measurement

Accuracy dimension is a cornerstone of modern-day commercial operations, supplying many benefits that can dramatically improve item quality and functional performance. By ensuring that dimensions are constant and exact, services can minimize irregularity in manufacturing processes, leading to even more consistent items. This harmony not only fulfills client expectations however additionally lessens waste, as less defective things make it to the last click to investigate phases of production.

Additionally, precision dimension promotes compliance with industry standards and laws. Accurate dimensions are important best site for meeting security and quality benchmarks, which can protect companies from expensive fines and reputational damage. Making use of advanced dimension innovations, such as galvanometer scanners, enables quick information procurement and evaluation, additional enhancing procedures.

On top of that, precision measurement improves decision-making abilities within companies. By supplying trusted information, it enables informed tactical preparation and source allowance. In a competitive market, these benefits can lead to boosted success and market share.

Inevitably, the integration of accuracy measurement right into industrial operations is not merely a choice; it is a need for organizations seeking to grow in a progressively demanding atmosphere. galvanometer scanner. The benefits expand beyond immediate gains, positioning firms for long-term success

Conclusion

In conclusion, galvanometer scanners function as crucial instruments in accuracy measurement applications, boosting the precision and rate of laser beam control throughout various industries. Their combination into processes such as laser cutting, marking, and biomedical imaging highlights their significance in enhancing functional effectiveness and ensuring compliance with sector requirements. The benefits offered by these scanners, including decreased irregularity and improved data procurement, highlight their important role beforehand innovation and fostering innovation in competitive markets.

Galvanometer scanners have arised as critical tools in accuracy measurement applications, especially due to their impressive capacity to adjust laser beams with phenomenal rate and precision.Galvanometer scanners play a crucial role in laser scanning applications, where accuracy and speed are vital.In industrial settings, galvanometer scanners are instrumental in laser cutting and engraving, where they give regular and repeatable control over the click to investigate laser beam of light's position. In laser machining, galvanometer scanners direct laser beams with outstanding precision, assisting in intricate cutting, inscription, and noting jobs.In verdict, galvanometer scanners serve as vital instruments in precision measurement applications, boosting the accuracy and rate of laser light beam control across numerous markets.